All production processes, from raw materials that make the manufacture of capsules, is performed in our plant.

The material used in the manufacture of capsules is an aluminum alloy specially developed for this purpose, domestically manufactured as rolled strip of constant thickness within tight tolerances which makes the product mechanical characteristics also to be constant.

We use in our coating line resins specially developed for aluminum, resistant to autoclaving, ethylene oxide and irradiation sterilization processes.

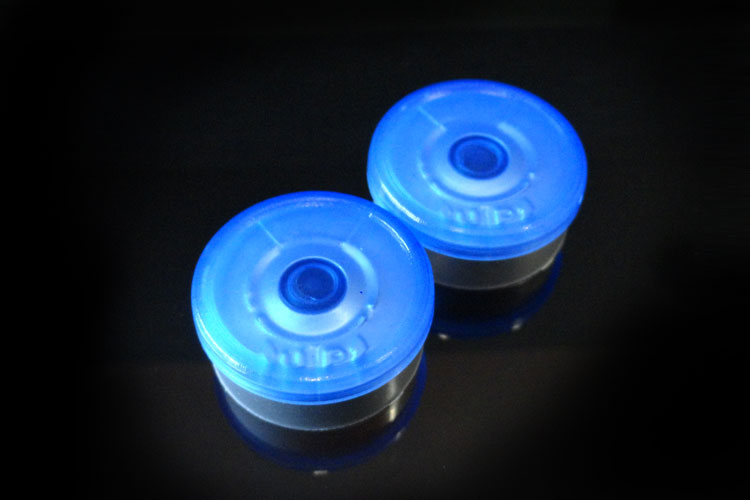

The stamping is made in automatic presses of high production, with our own moulds. The injection of the plastic cover, with fully automated injection machines. As a last step, we perform the assembly of both components also in a fully automatic way, by thermo-mechanical deformation.

- Main uses

- Dietary supplements

- Hair ampoules

- Bone tissue

- Collagen membranes

- Lyophilized oncological injectables

- Solid injectable beta-lactam

- Antihistamines

- Vaccines

- Diagnostic reagents

- Blood cultures